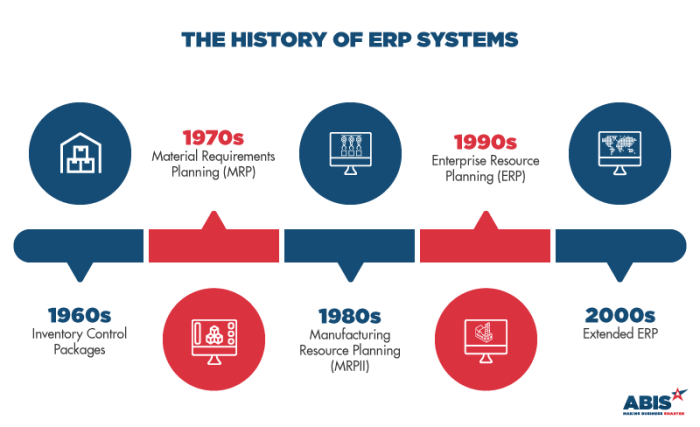

ERP Software History reveals a fascinating evolution, from rudimentary systems managing isolated business functions to the sophisticated, integrated solutions prevalent today. Early limitations of standalone applications spurred the development of Material Requirements Planning (MRP), a crucial precursor to the integrated Enterprise Resource Planning (ERP) systems we know. This journey encompasses the shifts from mainframe and client-server architectures to the cloud-based solutions dominating the modern business landscape.

This exploration delves into the key technological advancements, influential players, and evolving functionalities that have shaped ERP’s trajectory. We’ll examine the impact on various industries, the challenges of implementation and integration, and the exciting future trends promising even greater efficiency and transformative potential for businesses worldwide.

Early Days of ERP

Before the advent of integrated software systems, businesses relied on a patchwork of disparate applications to manage their various functions. Accounting was handled by one system, inventory by another, and sales by yet another. Information was often stored in silos, making it difficult to gain a holistic view of the business and hindering efficient decision-making. Data entry was duplicated across systems, increasing the likelihood of errors and inconsistencies. This fragmented approach created significant challenges in terms of reporting, analysis, and overall operational efficiency.

The limitations of these standalone applications were numerous. Lack of integration meant that data couldn’t be easily shared between departments, leading to delays and inefficiencies. For example, a sales order might not be automatically reflected in inventory levels, resulting in stockouts or overstocking. Reconciling data across different systems was a time-consuming and error-prone process. Reporting across the entire business was difficult, if not impossible, hindering strategic planning and performance monitoring. The lack of a unified system also made it challenging to implement consistent business processes across different locations or departments.

The Rise of Material Requirements Planning (MRP)

Material Requirements Planning (MRP) emerged in the 1960s as a response to the limitations of managing inventory and production planning with manual methods. Initially developed by Joseph Orlicky at IBM, MRP was a groundbreaking system that used a bill of materials (BOM) to calculate the precise quantities of raw materials needed to meet production schedules. This significantly improved inventory management by reducing waste and ensuring that the necessary materials were available when needed. While MRP focused primarily on production planning and inventory control, it represented a significant step towards integrating different business functions. Its success demonstrated the value of using computer systems to coordinate various aspects of a business, laying the groundwork for the development of more comprehensive integrated systems. Early MRP systems were often standalone applications, but they paved the way for the integrated systems that would eventually become known as ERP. The ability to link production planning with inventory control was a significant leap forward, showing the potential for streamlining business processes through data integration.

The Rise of Client-Server Architecture in ERP

The shift from mainframe-based ERP systems to client-server architectures marked a significant turning point in the history of enterprise resource planning. This transition, driven by advancements in networking and computing power, fundamentally altered how ERP systems were developed, deployed, and used, ultimately making them more accessible and adaptable to the evolving needs of businesses. The impact was profound, reshaping the landscape of enterprise software and paving the way for the modern ERP systems we know today.

The adoption of client-server architecture dramatically impacted the development and deployment of ERP systems. Mainframe systems, with their centralized processing, were expensive to implement and maintain, requiring specialized skills and infrastructure. Client-server systems, in contrast, distributed processing power, allowing users to interact with the ERP system through individual workstations (clients) that connected to a central server. This decentralized approach reduced the burden on the central mainframe, enabling greater scalability and allowing for more users to access the system concurrently. Deployment became simpler and more flexible, with less reliance on specialized hardware and personnel.

Client-Server ERP Systems Compared to Mainframe-Based Systems

Early client-server ERP systems offered several advantages over their mainframe predecessors. Mainframe systems were characterized by their monolithic design, where all processing occurred on a single, powerful machine. This centralized approach, while providing a high degree of data integrity, was also inflexible and difficult to scale. Updates and maintenance were complex and often required system downtime. Client-server systems, however, allowed for modularity and scalability. Individual components of the ERP system could be updated or replaced without impacting the entire system. This modularity also made it easier to integrate with other systems and adapt to changing business requirements. Further, the distributed processing nature of client-server systems improved response times for users, as processing was shared between the client workstations and the server. The user interface also became more user-friendly, moving away from the complex command-line interfaces typical of mainframe systems towards more intuitive graphical user interfaces (GUIs).

Challenges of Managing and Maintaining Client-Server ERP Infrastructures

Despite the advantages, managing and maintaining client-server ERP infrastructures presented unique challenges. The distributed nature of the system introduced complexities in data management and security. Ensuring data consistency across multiple client workstations required robust mechanisms for data synchronization and backup. Maintaining security also became more difficult, as each client workstation represented a potential entry point for unauthorized access. Network infrastructure became critical, requiring reliable and high-bandwidth connections to support the communication between clients and the server. Managing software updates and patches across a large number of client workstations was also a significant undertaking, demanding careful planning and coordination. Finally, the increased number of hardware components involved (servers, workstations, network devices) resulted in higher overall infrastructure costs and increased complexity in system administration. For example, a large company might face significant challenges in coordinating updates across hundreds or thousands of individual client workstations, a task that requires specialized software and expertise. This complexity contributed to the rising popularity of newer, more centralized architectures in later years.

The Impact of the Internet and Web Technologies

The advent of the internet and related web technologies profoundly reshaped the ERP landscape, transitioning it from primarily client-server architectures to the widely adopted web-based solutions we see today. This shift was driven by several key technological advancements and offered significant improvements in accessibility and functionality.

The proliferation of web browsers with standardized interfaces, coupled with advancements in network infrastructure and bandwidth, made accessing applications over the internet both feasible and efficient. Crucially, the development of robust web application frameworks and programming languages specifically designed for web development provided the necessary tools to build complex, scalable, and secure ERP systems accessible through a simple web browser. The rise of relational databases, capable of handling large volumes of data efficiently, also played a vital role.

Web-Based ERP System Functionality and Accessibility

Web-based ERP systems offer several advantages over their client-server predecessors. Perhaps the most significant is accessibility. Client-server systems required dedicated client software installed on each user’s machine, limiting access to those with the necessary hardware and software. Web-based systems, in contrast, are accessible from any device with an internet connection and a web browser, significantly increasing user reach and flexibility. This accessibility also extends to remote users and geographically dispersed teams, fostering better collaboration and real-time data sharing.

Furthermore, web-based ERP systems generally benefit from simplified maintenance and upgrades. Instead of deploying updates to each individual client machine, updates are centrally managed on the server, simplifying the process and reducing administrative overhead. This also ensures that all users are always working with the latest version of the software, minimizing inconsistencies and errors. Finally, web-based systems often offer better scalability, allowing businesses to easily expand their ERP system to accommodate growing user bases and increasing data volumes without significant infrastructure changes.

Generational Comparison of ERP Systems

The following table compares the key features of different generations of ERP systems:

| Feature | Mainframe ERP | Client-Server ERP | Web-Based ERP |

|---|---|---|---|

| Architecture | Centralized, mainframe-based | Distributed, client-server based | Centralized, cloud-based or web-server based |

| Accessibility | Limited, typically via terminals | Accessible from client machines with dedicated software | Accessible from any device with internet access and a web browser |

| Scalability | Limited scalability, expensive upgrades | Moderate scalability, upgrades can be complex | Highly scalable, easy upgrades |

| Maintenance | Complex and time-consuming | Complex and time-consuming, requires individual client updates | Simplified, centralized updates |

| Cost | High initial investment, high ongoing maintenance costs | High initial investment, significant ongoing maintenance costs | Variable costs, often subscription-based, lower maintenance costs |

| Examples | Early IBM ERP systems | SAP R/3 (early versions), Oracle Financials (early versions) | SAP S/4HANA Cloud, Oracle Cloud ERP, Microsoft Dynamics 365 |

The Emergence of Cloud-Based ERP

The shift towards cloud-based ERP systems marked a significant turning point in the evolution of enterprise resource planning. Driven by the increasing affordability and accessibility of cloud computing infrastructure, coupled with the growing demand for scalable and cost-effective solutions, cloud ERP rapidly gained traction. This transition offered businesses a compelling alternative to traditional on-premise deployments, fundamentally altering how organizations manage their core business processes.

The advantages and disadvantages of cloud-based ERP solutions compared to on-premise deployments are numerous and often depend on the specific needs and circumstances of the business. While cloud solutions offer greater flexibility and scalability, on-premise systems provide greater control and customization. A thorough understanding of these trade-offs is crucial for informed decision-making.

Cloud ERP Deployment Models and Their Impact on Adoption

Different cloud deployment models—Software as a Service (SaaS), Platform as a Service (PaaS), and Infrastructure as a Service (IaaS)—offer varying levels of control and responsibility. SaaS, the most common model for ERP, provides a complete, ready-to-use solution hosted by the vendor. PaaS offers more control, allowing businesses to customize their applications and manage their own databases. IaaS provides the most control, allowing businesses to manage their own infrastructure, including servers, operating systems, and databases. The choice of deployment model significantly influences the cost, complexity, and level of customization available to the business. For example, SaaS ERP systems generally have lower initial costs and require less IT expertise, making them attractive to smaller businesses, while IaaS solutions offer greater flexibility but require more significant IT investment and expertise.

Examples of Successful Cloud-Based ERP Implementations

Numerous organizations across various industries have successfully implemented cloud-based ERP systems. In the retail sector, companies like Zara have leveraged cloud ERP to optimize their supply chain and improve inventory management, leading to increased efficiency and reduced costs. Their cloud-based system enables real-time data analysis, allowing for faster decision-making and improved responsiveness to changing market demands. Similarly, in the manufacturing industry, companies like Siemens have implemented cloud ERP solutions to improve collaboration and communication across their global operations. This allows for better coordination of production processes, improved quality control, and enhanced responsiveness to customer needs. In the healthcare sector, cloud ERP systems have helped hospitals and clinics improve patient care by streamlining administrative processes and improving data sharing. These examples highlight the versatility and effectiveness of cloud-based ERP solutions across diverse business contexts.

Key Players and Pioneers in the ERP Industry

The Enterprise Resource Planning (ERP) software market has been shaped by a dynamic interplay of innovation, competition, and strategic acquisitions. Several companies have emerged as dominant players, each with its unique approach to market penetration and product development. Examining their histories reveals key trends and influences in the evolution of ERP.

The development and widespread adoption of ERP systems were not the work of a single entity, but rather a collaborative effort from numerous companies, each contributing to different aspects of the technology. Their strategies, from focusing on specific industry verticals to developing comprehensive suites, significantly influenced the landscape of ERP solutions. Analyzing their timelines and market approaches illuminates the key factors driving the ERP industry’s growth and evolution.

Major ERP Vendors and Their Strategies

Several vendors have consistently held significant market share throughout the ERP industry’s history. Their strategies varied, influencing the direction and features of ERP systems. Some focused on vertical market specialization, tailoring their solutions to specific industries, while others opted for a horizontal approach, developing generalized solutions adaptable to various sectors. Others emphasized technological innovation, pioneering new architectures and functionalities.

- SAP: SAP, a German multinational software corporation, has been a dominant force in the ERP market since its inception. Its strategy has been characterized by a focus on large enterprise clients, offering comprehensive and highly customizable solutions. SAP’s R/3 system, launched in 1972, marked a pivotal moment in the development of ERP software, establishing the company as a market leader. Their later embrace of cloud technologies, with solutions like SAP S/4HANA, has further solidified their position.

- Oracle: Oracle, initially known for its database management systems, expanded into the ERP market through acquisitions and organic growth. Their strategy involved integrating their database technology with ERP applications, providing a robust and scalable platform. Oracle’s acquisition of PeopleSoft and Siebel Systems significantly broadened their ERP portfolio and market reach.

- Microsoft Dynamics 365: Microsoft leveraged its extensive user base and existing software ecosystem to enter the ERP market with Dynamics 365. Their strategy focuses on ease of use and integration with other Microsoft products, targeting a broader range of businesses, from small and medium-sized enterprises (SMEs) to larger corporations. This accessibility and integration have been key to their success.

- Infor: Infor focuses on industry-specific ERP solutions, tailoring its products to the unique needs of different sectors. This vertical market specialization has allowed them to gain a strong foothold in specific industries, offering specialized functionalities and expertise.

Timeline of Significant Milestones for Major ERP Companies

A chronological overview of key milestones for leading ERP vendors highlights the evolution of the industry and the strategic decisions that shaped their trajectories.

| Company | Year | Milestone |

|---|---|---|

| SAP | 1972 | Launch of R/2 |

| SAP | 1992 | Launch of R/3 |

| Oracle | 1990s | Acquisitions of various ERP companies, expanding its product portfolio |

| Oracle | 2005 | Release of Oracle E-Business Suite 11i |

| Microsoft | 2003 | Launch of Microsoft Dynamics GP |

| Microsoft | 2016 | Launch of Dynamics 365 |

| Infor | 2000s | Series of acquisitions focusing on vertical market solutions |

The Evolution of ERP Functionality

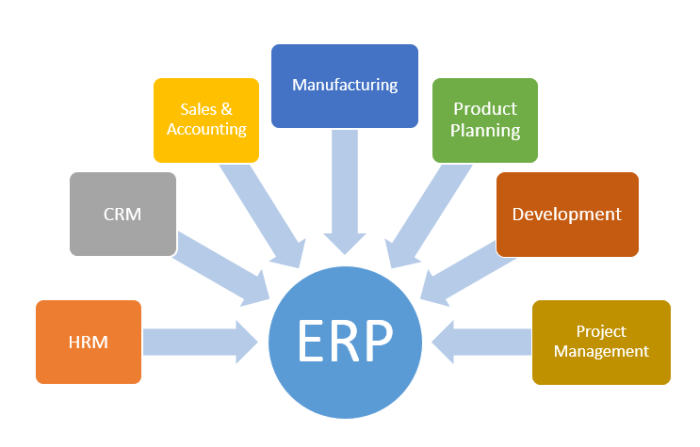

Early ERP systems focused primarily on core business functions like finance, manufacturing, and human resources. These modules provided integrated data management and process automation within their respective areas. However, the evolution of ERP has been marked by a significant expansion of functionality, driven by the need for greater business integration and improved decision-making capabilities. This expansion has led to the integration of previously disparate systems and the emergence of new capabilities.

The integration of Customer Relationship Management (CRM), Supply Chain Management (SCM), and Business Intelligence (BI) functionalities represents a pivotal shift in ERP’s capabilities. These additions have transformed ERP from a primarily operational system into a strategic tool for managing relationships, optimizing supply chains, and gaining valuable insights from business data. This broadened scope has enabled organizations to achieve a more holistic view of their operations and make more informed, data-driven decisions.

Expansion Beyond Core Modules

The initial core modules of finance, manufacturing, and HR formed the foundation of early ERP systems. Over time, however, the demand for more comprehensive solutions led to the development of modules addressing specific industry needs and business processes. This includes project management, procurement, quality management, and maintenance management, among others. For instance, a manufacturing company might integrate a quality management module to track defects and improve product quality, while a construction firm might leverage a project management module to manage complex projects effectively. This expansion allows organizations to tailor their ERP systems to their specific operational requirements, maximizing efficiency and streamlining workflows across diverse departments.

Integration of CRM, SCM, and BI

The integration of CRM, SCM, and BI functionalities has significantly enhanced the strategic value of ERP systems. CRM modules facilitate the management of customer interactions, sales processes, and marketing campaigns, providing a 360-degree view of each customer. This allows businesses to personalize customer experiences, improve customer satisfaction, and increase sales. SCM modules optimize the flow of goods and services throughout the supply chain, from procurement to delivery, enhancing efficiency and reducing costs. This includes managing inventory, optimizing logistics, and collaborating with suppliers. Finally, BI modules provide advanced analytics and reporting capabilities, enabling organizations to gain insights from their data, identify trends, and make informed business decisions. These integrated functionalities provide a holistic view of the business, allowing for better coordination and strategic planning.

Evolution of Key ERP Modules and Capabilities

| Module | Early Capabilities (1990s) | Mid-Stage Capabilities (2000s) | Modern Capabilities (2010s-Present) |

|---|---|---|---|

| Finance | Basic accounting, financial reporting | Advanced budgeting, forecasting, financial consolidation | Real-time financial dashboards, integrated tax compliance, predictive analytics |

| Manufacturing | Production planning, inventory management | Materials requirements planning (MRP), capacity planning | Advanced process manufacturing, supply chain visibility, predictive maintenance |

| Human Resources | Payroll, employee records | Recruitment, performance management, benefits administration | Talent management, learning management, employee self-service portals |

| CRM | Not typically integrated | Contact management, sales force automation | Integrated marketing automation, customer service portals, social media integration |

| SCM | Limited integration with other modules | Inventory management, procurement | End-to-end supply chain visibility, demand forecasting, collaborative planning |

| BI | Limited reporting capabilities | Data warehousing, basic reporting and analytics | Advanced analytics, predictive modeling, data visualization dashboards |

The Role of ERP in Business Transformation

ERP systems have fundamentally reshaped how businesses operate, moving them from disparate, siloed systems to integrated, streamlined workflows. This transformation is driven by ERP’s ability to centralize data, automate processes, and provide real-time visibility across the entire organization. The impact spans various facets of a business, significantly improving efficiency, reducing costs, and enhancing competitiveness in the global marketplace.

ERP systems have facilitated business process re-engineering and automation by providing a single, unified platform for managing various business functions. This integration eliminates data redundancy, reduces manual data entry, and automates repetitive tasks, freeing up employees to focus on higher-value activities. The automation capabilities extend to areas such as procurement, inventory management, production planning, and financial reporting, resulting in significant time and cost savings. For example, automated purchase order generation based on pre-defined inventory levels eliminates manual intervention and potential errors.

ERP’s Impact on Supply Chain Management

Effective supply chain management is critical for maintaining a competitive edge. ERP systems enhance this by providing real-time visibility into inventory levels, production schedules, and supplier performance. This allows businesses to optimize their supply chain, reduce lead times, and minimize stockouts or overstocking. Features like demand forecasting, integrated logistics management, and collaborative supplier portals contribute to improved efficiency and reduced costs. For instance, a company using an ERP system can accurately predict future demand, enabling them to procure raw materials proactively and avoid costly production delays.

ERP’s Impact on Customer Relationship Management

ERP systems integrate customer data from various sources, providing a 360-degree view of each customer. This holistic view enables businesses to personalize interactions, improve customer service, and increase customer loyalty. Features such as customer relationship management (CRM) modules, integrated sales order processing, and personalized marketing tools empower businesses to build stronger relationships with their customers. For example, an ERP system can track customer purchase history, enabling targeted marketing campaigns and personalized product recommendations, thus improving customer satisfaction and retention.

ERP’s Impact on Decision-Making

ERP systems provide real-time access to accurate and comprehensive data, empowering businesses to make informed decisions. The centralized data repository allows for quick analysis of key performance indicators (KPIs), enabling managers to identify trends, anticipate problems, and proactively adjust strategies. Advanced analytics and reporting tools further enhance decision-making by providing insights into areas such as sales performance, production efficiency, and financial health. For example, real-time sales data allows for immediate adjustments to production schedules, preventing overproduction or stockouts. Financial dashboards provide a clear picture of the company’s financial performance, enabling quick identification of potential problems and proactive mitigation strategies.

Examples of ERP-Driven Business Improvements

Many companies have leveraged ERP systems to achieve significant improvements in efficiency, cost reduction, and competitiveness. Consider a manufacturing company that implemented an ERP system, automating its production planning and inventory management. This resulted in a 15% reduction in production lead times and a 10% decrease in inventory holding costs. Similarly, a retail company using an ERP system with integrated CRM functionality saw a 20% increase in customer retention and a 15% increase in sales. These examples illustrate the transformative power of ERP in driving business success.

Challenges and Future Trends in ERP

Enterprise Resource Planning (ERP) systems, while offering significant benefits, present ongoing challenges in implementation, customization, and integration. Simultaneously, rapid technological advancements are shaping the future of ERP, leading to both opportunities and new hurdles. Understanding these aspects is crucial for organizations seeking to leverage ERP effectively.

ERP implementation is a complex undertaking, often requiring significant investment of time, resources, and expertise. Successful implementation hinges on careful planning, thorough data migration, robust user training, and ongoing system maintenance. Failure to address these areas can lead to project delays, budget overruns, and ultimately, a system that fails to deliver its promised value.

ERP Implementation Challenges

The complexity of ERP systems, coupled with the need for extensive customization to meet specific business needs, often leads to difficulties. Integration with existing legacy systems can also prove problematic, requiring significant effort and potentially leading to data inconsistencies. Resistance to change from employees unfamiliar with new systems is another common hurdle. For example, a large manufacturing company might face challenges integrating its ERP with older machinery control systems, necessitating significant investment in custom interfaces and training. Similarly, a retail company undergoing an ERP upgrade might encounter resistance from sales staff accustomed to older point-of-sale systems.

ERP Customization and Integration Challenges

Customization, while enabling a tailored fit, can increase complexity and maintenance costs. Changes to the core ERP system can be time-consuming and expensive, and may introduce vulnerabilities if not properly managed. Integration with third-party applications and external data sources also presents challenges, requiring careful consideration of data formats, security protocols, and potential conflicts. A hypothetical scenario involves a financial institution integrating its ERP with a fraud detection system. This integration requires robust security measures to protect sensitive financial data and ensure seamless data exchange without compromising either system’s performance.

Emerging Trends in ERP: AI, Machine Learning, and Blockchain

Artificial intelligence (AI) and machine learning (ML) are transforming ERP systems by enabling predictive analytics, automated decision-making, and improved operational efficiency. AI-powered chatbots can provide instant support to users, while ML algorithms can predict demand, optimize inventory levels, and detect anomalies in financial transactions. Blockchain technology offers enhanced security and transparency by providing an immutable record of transactions. Its potential applications in ERP include supply chain management, tracking assets, and improving contract management.

The Impact of Emerging Technologies on the Future of ERP

The integration of AI, ML, and blockchain is poised to significantly enhance ERP functionality and capabilities. AI-driven predictive analytics can provide valuable insights into business operations, enabling proactive decision-making and improved resource allocation. ML algorithms can automate repetitive tasks, freeing up human resources for more strategic activities. Blockchain can enhance data security and transparency, fostering trust and collaboration within the supply chain. For example, a logistics company could use blockchain to track shipments in real-time, providing greater visibility and accountability to all stakeholders. This increased transparency could significantly reduce the risk of fraud and improve efficiency. A retailer might leverage AI-driven demand forecasting to optimize inventory levels, minimizing storage costs and preventing stockouts.

The Impact of ERP on Different Industries

Enterprise Resource Planning (ERP) systems have profoundly impacted various industries, tailoring their functionalities to meet specific sector needs. While the core principles of integrated data management remain consistent, the implementation and application of ERP differ significantly across sectors, reflecting unique operational structures, regulatory environments, and competitive landscapes. This section explores the diverse ways ERP has transformed key industries.

ERP in Manufacturing

Manufacturing is arguably the sector where ERP systems initially found their most significant foothold. The complex processes involved—from procurement and production planning to inventory management and quality control—benefit immensely from the integrated data visibility provided by ERP. Manufacturers use ERP to optimize production schedules, manage supply chains effectively, track materials in real-time, and improve overall efficiency. Specific ERP modules, such as Manufacturing Execution Systems (MES), are often integrated to provide real-time visibility into the shop floor, enabling proactive adjustments to production processes. The automotive industry, for instance, heavily relies on ERP systems to manage its intricate global supply chains and complex manufacturing processes, ensuring timely delivery of vehicles and parts.

ERP in Retail, Erp software history

The retail industry, with its focus on customer relationship management (CRM), inventory control, and point-of-sale (POS) systems, has also significantly benefited from ERP implementation. Retail ERP systems integrate data from various channels, including online stores, physical stores, and warehouses, providing a unified view of inventory levels, sales data, and customer information. This integrated view allows retailers to optimize stock levels, personalize marketing campaigns, and improve customer service. For example, a major clothing retailer might use ERP to track sales trends, predict future demand, and adjust purchasing orders accordingly, minimizing stockouts and maximizing profitability. Effective inventory management, facilitated by ERP, is critical for reducing waste and optimizing profitability in this highly competitive sector.

ERP in Healthcare

The healthcare industry presents unique challenges for ERP implementation due to stringent regulatory compliance requirements, complex billing processes, and the sensitive nature of patient data. However, ERP systems are increasingly being adopted to improve operational efficiency, streamline patient care, and manage financial resources effectively. Healthcare-specific ERP systems often include modules for patient management, electronic health records (EHR), billing and claims processing, and regulatory compliance. For example, a large hospital system might use ERP to manage patient appointments, track medical supplies, and streamline billing processes, improving overall operational efficiency and reducing administrative costs. Data security and privacy are paramount considerations in healthcare ERP deployments, necessitating robust security measures and adherence to regulations like HIPAA.

Summary: Erp Software History

The history of ERP software showcases a remarkable journey of technological innovation and adaptation to the ever-changing needs of businesses. From its humble beginnings in managing materials to its current role as a central nervous system for organizations of all sizes, ERP has demonstrably revolutionized business processes. The future promises even more integration, leveraging AI and other emerging technologies to further streamline operations and unlock new levels of efficiency and strategic advantage. Understanding this history is crucial for navigating the complexities of modern ERP systems and harnessing their full potential.

Early ERP systems emerged from material requirements planning (MRP) software, gradually evolving to integrate various business functions. The need for comprehensive data management fueled the development of sophisticated erp software solutions , leading to the modern, integrated systems we see today. Understanding this historical progression is crucial for appreciating the current capabilities and future potential of ERP software.

The evolution of ERP software spans decades, from its origins in materials requirement planning to the sophisticated systems we see today. A significant player in the modern ERP landscape is Workday, a cloud-based solution; you can learn more about its capabilities and features by checking out this resource on erp software workday. Understanding Workday’s role helps illustrate the ongoing advancements and diversification within the broader history of ERP software development.