ERP software software is revolutionizing how businesses manage their operations. From streamlining inventory to automating financial processes, ERP systems offer a centralized platform for managing crucial business data. This guide delves into the core functionalities, selection process, implementation strategies, and future trends of ERP software, equipping you with the knowledge to leverage this powerful technology effectively.

Understanding the different types of ERP deployments—cloud, on-premise, and hybrid—is crucial for choosing the optimal solution. We’ll explore the key features of each, weigh the pros and cons, and guide you through selecting the right ERP system to meet your specific business needs and budget. This includes a detailed look at the cost implications, security considerations, and the potential return on investment.

Defining ERP Software

Enterprise Resource Planning (ERP) software is a system designed to integrate all facets of a business, from planning and purchasing to manufacturing and sales. It streamlines operations by centralizing data and automating processes, leading to improved efficiency and better decision-making. Think of it as a central nervous system for a company, connecting all its vital functions.

ERP systems provide a holistic view of an organization’s operations, enabling better coordination and collaboration across departments. This unified approach helps businesses optimize resource allocation, reduce costs, and improve overall performance. A well-implemented ERP system can significantly enhance a company’s competitiveness.

Core Functionalities of ERP Systems

The core functionalities of an ERP system are extensive and vary depending on the specific software and the industry. However, most systems incorporate modules focused on key business areas. These modules typically include financial management (accounting, budgeting, reporting), human resource management (payroll, recruitment, employee records), supply chain management (procurement, inventory, logistics), and customer relationship management (sales, marketing, customer service). Many systems also include manufacturing, project management, and business intelligence modules. The integration of these modules is a key strength of ERP, allowing for seamless data flow between departments.

ERP Software Deployment Types

Businesses have several options when it comes to deploying ERP software. The choice depends on factors such as budget, IT infrastructure, security requirements, and scalability needs.

- Cloud-based ERP: This deployment model involves accessing the ERP system through the internet, hosted by a third-party provider. It offers flexibility, scalability, and reduced upfront costs as businesses only pay for what they use. Examples include SaaS (Software as a Service) offerings from companies like Salesforce and SAP. The vendor handles all infrastructure maintenance and updates.

- On-premise ERP: In this model, the ERP software is installed and maintained on the company’s own servers. It offers greater control over data security and customization but requires significant upfront investment in hardware and IT personnel for installation, maintenance, and updates. This approach is suitable for organizations with high security requirements or those needing highly specific customizations.

- Hybrid ERP: This approach combines elements of both cloud and on-premise deployments. Certain modules or functionalities might be hosted in the cloud, while others remain on-premise. This provides a balance between control and flexibility, allowing businesses to tailor their deployment to their specific needs. For example, a company might host sensitive financial data on-premise while utilizing cloud-based CRM for better customer accessibility and scalability.

Key Features of ERP Software

Enterprise Resource Planning (ERP) software offers a comprehensive suite of integrated applications that streamline business processes across various departments. Understanding the core functionalities is crucial for selecting the right system to meet specific organizational needs. This section details essential features and explores the distinctions between cloud-based and on-premise deployments.

Essential ERP Software Features

The following table Artikels key features commonly found in most ERP systems. These features work together to provide a unified view of business operations, facilitating better decision-making and improved efficiency.

| Feature | Description | Feature | Description |

|---|---|---|---|

| Financial Management | Handles accounting tasks like general ledger, accounts payable, accounts receivable, budgeting, and financial reporting. Provides real-time financial insights. | Human Capital Management (HCM) | Manages employee information, payroll, benefits, recruitment, and performance management. Streamlines HR processes and improves employee engagement. |

| Supply Chain Management (SCM) | Optimizes the flow of goods and services from procurement to delivery. Includes inventory management, order processing, and logistics. Improves supply chain visibility and efficiency. | Customer Relationship Management (CRM) | Manages customer interactions, sales processes, and marketing campaigns. Provides a centralized view of customer data to enhance customer satisfaction and loyalty. |

| Manufacturing Management | Manages production planning, scheduling, and execution. Tracks materials, labor, and production costs. Improves manufacturing efficiency and reduces waste. | Project Management | Facilitates project planning, execution, and monitoring. Tracks project progress, resources, and budgets. Improves project completion rates and reduces delays. |

| Business Intelligence (BI) and Reporting | Provides tools for data analysis and reporting. Generates customized reports and dashboards to track key performance indicators (KPIs). Supports data-driven decision-making. | Inventory Management | Tracks inventory levels, monitors stock movements, and manages warehouse operations. Minimizes stockouts and reduces storage costs. |

Cloud-Based vs. On-Premise ERP Systems

Cloud-based ERP systems are hosted on a vendor’s servers and accessed via the internet, while on-premise systems are installed and maintained on the company’s own servers. Cloud-based systems offer scalability, accessibility, and reduced IT infrastructure costs, while on-premise systems provide greater control and customization but require significant upfront investment and ongoing maintenance. A key difference lies in the level of control and customization; cloud solutions often offer pre-configured features, while on-premise systems allow for more tailored configurations. Security is another consideration; both options offer robust security measures, but the responsibility for security management differs.

Benefits of ERP System Implementation, Erp software software

Implementing an ERP system offers significant benefits to businesses of all sizes. Small businesses benefit from streamlined operations and improved efficiency, while larger enterprises gain enhanced visibility and control over their complex operations. For example, a small retail business might use an ERP system to manage inventory, track sales, and process payments more efficiently. A large manufacturing company could leverage an ERP system to optimize its supply chain, improve production planning, and manage its global workforce more effectively. Improved data visibility, reduced operational costs, and enhanced decision-making capabilities are common advantages across all business sizes. The specific benefits realized will vary depending on the size and industry of the business, as well as the specific features and functionalities implemented within the ERP system.

ERP Software Selection Process

Choosing the right ERP software is a crucial decision for any business, impacting operational efficiency, data management, and overall growth. A well-defined selection process ensures the chosen system aligns with specific business needs and long-term goals, minimizing disruption and maximizing return on investment. This process requires careful planning, thorough research, and a comprehensive evaluation of various vendors and their offerings.

The ERP software selection process should be approached systematically, following a structured methodology to ensure a successful implementation. A phased approach, from initial needs assessment to final vendor selection and contract negotiation, is vital. Ignoring any step can lead to costly mistakes and ultimately, an unsuitable system.

Step-by-Step Guide for ERP Software Selection

A structured approach to ERP software selection significantly improves the chances of choosing a system that meets business requirements. This step-by-step guide Artikels the key phases involved.

- Needs Assessment and Requirements Definition: Clearly define your business needs and objectives. Identify key processes to be supported by the ERP system (e.g., finance, supply chain, human resources). Document specific requirements, considering scalability and future growth.

- Vendor Research and Shortlisting: Research potential ERP vendors based on your defined requirements. Consider factors such as industry experience, software capabilities, implementation methodology, and customer support. Create a shortlist of vendors who meet your preliminary criteria.

- Request for Proposal (RFP) and Demonstrations: Send RFPs to your shortlisted vendors, outlining your specific requirements and seeking detailed proposals. Schedule demonstrations to assess the software’s functionality and user-friendliness. Compare proposals based on features, pricing, and implementation timelines.

- Proof of Concept (POC): Conduct a POC to test the software’s capabilities in a real-world scenario. This allows you to evaluate the software’s performance and identify potential integration challenges. This step helps validate the vendor’s claims and ensures the software meets your specific needs.

- Vendor Evaluation and Selection: Evaluate the shortlisted vendors based on the RFP responses, demonstrations, and POC results. Consider factors such as total cost of ownership (TCO), vendor reputation, and long-term support. Select the vendor that best meets your requirements and offers the best value.

- Contract Negotiation and Implementation: Negotiate the contract with the selected vendor, clearly defining the scope of work, timelines, and payment terms. Collaborate with the vendor on the implementation plan, ensuring a smooth transition to the new ERP system.

Factors to Consider When Evaluating ERP Vendors

Evaluating ERP vendors requires a comprehensive approach, considering various aspects beyond just software features. A checklist approach helps ensure nothing is overlooked.

- Functionality and Features: Does the software meet all your business requirements? Does it offer the necessary modules and functionalities? Consider scalability and future needs.

- Implementation Methodology and Timeline: What is the vendor’s implementation approach? What is the estimated timeline for implementation? How will the vendor support your team throughout the process?

- Cost and Total Cost of Ownership (TCO): What are the initial costs, ongoing maintenance costs, and other associated expenses? Consider the long-term implications of the TCO.

- Vendor Reputation and Experience: Research the vendor’s reputation and track record. Check client testimonials and reviews. Consider their experience in your industry.

- Integration Capabilities: How well does the software integrate with your existing systems? What integration tools and services are provided by the vendor?

- Customer Support and Training: What level of customer support is offered? What training programs are available for your employees?

- Scalability and Flexibility: Can the software adapt to your business’s future growth and changing needs? Is it easily customizable?

Importance of Due Diligence in ERP Software Selection

Thorough due diligence is paramount to avoid costly mistakes and ensure a successful ERP implementation. This involves a rigorous investigation of the vendor, the software, and the overall project scope.

Due diligence should encompass a comprehensive review of the vendor’s financial stability, track record, and customer references. It also includes a detailed analysis of the software’s capabilities, limitations, and potential risks. Finally, a thorough assessment of the implementation plan, including timelines, resources, and potential challenges, is crucial. Ignoring due diligence can lead to significant financial losses, operational disruptions, and project failure.

ERP Software Implementation

Implementing an ERP system is a significant undertaking, requiring careful planning, execution, and ongoing support. Success hinges on a well-defined strategy, strong project management, and the active participation of all stakeholders. The process is complex and multifaceted, demanding both technical expertise and a deep understanding of the organization’s business processes.

ERP implementation typically involves several distinct phases, each with its own set of challenges and considerations. A successful implementation requires a systematic approach, addressing potential risks proactively, and leveraging best practices to maximize the return on investment.

Stages of ERP Implementation

The implementation of an ERP system is generally divided into several key stages. These stages often overlap and require iterative refinement based on project progress and feedback. Understanding these phases is crucial for effective project management and resource allocation.

These stages typically include: Project Initiation and Planning, Gap Analysis and Requirements Definition, System Design and Configuration, Data Migration, Testing and Training, Go-Live and Post-Implementation Support.

Challenges and Risks of ERP Implementation

ERP implementation projects are notorious for their complexity and potential for delays and cost overruns. Several factors contribute to these challenges, including inadequate planning, insufficient user training, and unforeseen technical issues. Understanding these risks allows organizations to proactively mitigate them and improve the chances of a successful outcome.

Common challenges include: Resistance to change from employees, integration complexities with existing systems, inadequate data migration planning, insufficient user training, and lack of executive sponsorship. Risks can manifest as project delays, budget overruns, and ultimately, failure to achieve the intended benefits of the ERP system. For example, a poorly planned data migration can lead to data loss or inaccuracies, significantly impacting the system’s reliability and the organization’s ability to operate effectively. Similarly, inadequate user training can result in low adoption rates and decreased productivity, undermining the entire investment.

Best Practices for Successful ERP Implementation

Several best practices can significantly increase the likelihood of a successful ERP implementation. These practices encompass all stages of the project, from initial planning to post-implementation support. Adhering to these principles minimizes risks and maximizes the chances of realizing the full potential of the new system.

A structured approach is key to successful implementation. The following best practices should be considered:

- Clearly Define Project Scope and Objectives: Establish clear, measurable goals for the ERP implementation, ensuring all stakeholders are aligned on expectations.

- Develop a Comprehensive Implementation Plan: Create a detailed project plan outlining all tasks, timelines, and responsibilities. This plan should include contingency plans for addressing potential challenges.

- Secure Executive Sponsorship and Stakeholder Buy-in: Obtain strong support from senior management and ensure all key stakeholders are actively involved in the process.

- Thorough Requirements Gathering and Gap Analysis: Conduct a comprehensive analysis of the organization’s business processes to identify areas for improvement and ensure the ERP system meets all requirements.

- Choose the Right ERP Vendor and Implementation Partner: Select a vendor and partner with proven experience and a strong track record of successful implementations.

- Effective Change Management: Develop a comprehensive change management strategy to address employee concerns and ensure smooth transition to the new system.

- Comprehensive Testing and User Acceptance Testing (UAT): Conduct rigorous testing to identify and resolve any issues before going live. Involve end-users in UAT to ensure the system meets their needs.

- Phased Rollout: Consider a phased rollout approach to minimize disruption and allow for iterative improvements based on feedback.

- Post-Implementation Support and Maintenance: Provide ongoing support and maintenance to address any issues that arise after go-live and ensure the system continues to meet the organization’s needs.

Integration with Other Systems

ERP software’s power significantly increases when integrated with other business applications. This interconnectedness allows for a more streamlined and efficient workflow, breaking down data silos and fostering better decision-making across the organization. Effective integration is key to unlocking the full potential of an ERP system.

Seamless data exchange between an ERP system and other applications like Customer Relationship Management (CRM) and Supply Chain Management (SCM) systems is crucial for modern businesses. This integration eliminates the need for manual data entry and reconciliation, reducing errors and saving valuable time and resources. For example, sales data from a CRM system can be automatically transferred to the ERP system to update inventory levels and trigger procurement processes. Conversely, real-time inventory information from the ERP system can be shared with the SCM system to optimize logistics and planning.

Benefits of Seamless Integration

The advantages of integrated systems are numerous. Improved data accuracy is a primary benefit, stemming from the elimination of manual data entry. This reduces the risk of human error, leading to more reliable financial reports and operational insights. Automation of processes, facilitated by integration, streamlines workflows, boosts productivity, and frees up employees to focus on higher-value tasks. Better collaboration across departments is also fostered, as integrated systems provide a single source of truth, improving communication and transparency. Finally, enhanced decision-making is enabled by having a complete and accurate view of the entire business in real-time. Companies can respond more quickly to market changes and customer demands, gaining a competitive edge.

Integration Challenges and Strategies

Integrating different systems can present challenges. Data inconsistencies between systems, due to different data formats or structures, can hinder integration efforts. For instance, a CRM system might use different customer identifiers compared to the ERP system. Another challenge is the potential for incompatibility between software platforms and technologies. Older legacy systems might not be compatible with newer ERP software, requiring significant upgrades or replacements. Finally, security concerns related to data exchange and access control need careful consideration. Implementing robust security protocols is crucial to protect sensitive business data.

To overcome these challenges, a phased approach to integration is often recommended. Starting with a pilot project integrating a smaller subset of systems can help identify and address potential issues before a full-scale implementation. Data mapping and cleansing are crucial steps to ensure data consistency and accuracy across different systems. Selecting an ERP system with robust integration capabilities and compatibility with existing systems is also vital. Finally, investing in skilled personnel to manage and maintain the integrated systems is essential for long-term success. This may include internal IT staff or external consultants specializing in ERP integration.

Cost of ERP Software

Implementing an ERP system represents a significant investment for any business. Understanding the various cost components and potential return is crucial for making an informed decision. This section details the financial aspects of ERP adoption, encompassing licensing, implementation, and ongoing maintenance, and explores how these costs vary across different deployment models.

ERP Software Licensing Costs

ERP software licensing fees are typically based on the number of users, modules implemented, and the specific features required. The cost can range from a few thousand dollars for smaller businesses utilizing cloud-based solutions with limited functionality to millions for large enterprises implementing complex, on-premise systems. Factors influencing licensing costs include the vendor (e.g., SAP, Oracle, Microsoft Dynamics), the specific ERP software package chosen, and any add-on modules or customizations needed. For example, a small manufacturing company might pay a monthly subscription fee for a cloud-based ERP system with basic inventory management and accounting capabilities, while a large multinational corporation might pay a substantial upfront license fee for a comprehensive on-premise system with advanced supply chain management and analytics features. Negotiating favorable licensing terms with the vendor is essential.

ERP Software Implementation Costs

Implementation costs constitute a substantial portion of the total ERP project expense. These costs include project management fees, consulting services, data migration, system customization, training, and internal resources dedicated to the implementation process. The complexity of the implementation, the size of the organization, and the level of customization required all significantly impact these costs. For instance, a simple implementation of a cloud-based ERP system in a small business might cost a few tens of thousands of dollars, while a large-scale implementation in a global enterprise could easily reach hundreds of thousands or even millions of dollars. Careful planning and project management are essential to control implementation costs and prevent cost overruns.

ERP Software Maintenance Costs

Ongoing maintenance costs are incurred after the ERP system is implemented and include software updates, technical support, bug fixes, and system enhancements. These costs can be substantial, particularly for complex systems. Maintenance contracts are typically offered by the ERP vendor and can be structured as fixed annual fees or based on usage. The level of support required, the complexity of the system, and the vendor’s pricing structure all affect the overall maintenance costs. Regular system maintenance is crucial to ensure the ERP system continues to function optimally and to benefit from the latest features and security updates. For example, a small business might pay a few hundred dollars per month for maintenance, while a large enterprise might pay tens of thousands of dollars annually.

Total Cost of Ownership (TCO) for Different Deployment Models

The total cost of ownership (TCO) for ERP systems varies considerably depending on the deployment model chosen (cloud, on-premise, hybrid). Cloud-based deployments typically have lower upfront costs but may incur higher recurring costs over time. On-premise deployments involve significant upfront investment in hardware, software, and implementation but may have lower long-term operating costs. Hybrid deployments offer a compromise, combining elements of both cloud and on-premise models. A detailed comparison across these models requires a thorough analysis of the specific needs and circumstances of each organization. For instance, a small business with limited IT infrastructure might find a cloud-based deployment more cost-effective, while a large enterprise with stringent data security requirements might opt for an on-premise deployment despite the higher initial investment.

Return on Investment (ROI) from ERP System Implementation

The return on investment (ROI) from implementing an ERP system can be substantial but is not guaranteed. Businesses can expect improved operational efficiency, reduced costs, better inventory management, enhanced customer satisfaction, and improved decision-making capabilities. Quantifying the ROI requires careful analysis of cost savings, increased revenue, and other intangible benefits. For example, reduced inventory holding costs, improved production efficiency, and streamlined supply chain processes can all contribute to a positive ROI. A successful ERP implementation requires careful planning, effective project management, and ongoing support. The ROI calculation should consider both tangible and intangible benefits to obtain a complete picture. For example, a reduction in order processing time by 20% translates directly to cost savings and increased efficiency, while improvements in customer satisfaction are harder to quantify but contribute significantly to long-term business success. Many successful case studies showcase a significant ROI from ERP implementation, typically within a few years of the project’s completion.

Security and Data Management in ERP

Implementing and maintaining a robust ERP system necessitates a strong focus on security and data management. The sensitive nature of the data handled by ERP systems—financial records, customer information, employee details, and intellectual property—makes it a prime target for cyberattacks and data breaches. Effective security measures are crucial not only for compliance with regulations but also for protecting the organization’s reputation and maintaining business continuity.

ERP systems offer a centralized repository for critical business data, making comprehensive data management practices essential. This includes data governance, access control, data integrity, and disaster recovery planning. A well-structured approach to data management ensures data accuracy, consistency, and accessibility while minimizing risks associated with data loss or misuse.

Data Security Measures in ERP Systems

Effective data security involves a multi-layered approach. This includes implementing strong authentication mechanisms, such as multi-factor authentication (MFA), to prevent unauthorized access. Role-based access control (RBAC) ensures that only authorized personnel can access specific data and functionalities within the system. Regular security audits and penetration testing identify vulnerabilities and help organizations proactively address potential threats. Data encryption, both in transit and at rest, protects sensitive information from unauthorized access even if a breach occurs. Furthermore, robust change management processes minimize the risk of introducing security flaws during system updates or modifications. For example, a retail company might use MFA to protect access to its inventory management module, preventing unauthorized changes to stock levels. RBAC would ensure that only authorized personnel in the purchasing department can approve new vendor accounts.

Data Backup and Recovery Strategies

A comprehensive data backup and recovery strategy is critical for business continuity in the event of data loss due to hardware failure, cyberattacks, or natural disasters. Regular backups should be performed, ideally using a combination of on-site and off-site storage. The frequency of backups depends on the criticality of the data and the organization’s risk tolerance; some organizations might opt for daily or even hourly backups of crucial data. A well-defined recovery plan Artikels the procedures for restoring data in case of a system failure. This plan should include testing the recovery process regularly to ensure its effectiveness. For instance, a manufacturing company might employ a 3-2-1 backup strategy (three copies of data on two different media types, with one copy stored offsite) to protect against data loss from various scenarios. Regular testing of the recovery plan would validate that the company can restore its operations within an acceptable timeframe.

Protecting Sensitive Business Data with ERP Software

ERP systems provide inherent features to manage and protect sensitive data. Data masking and anonymization techniques can be used to protect sensitive information during development, testing, or reporting. Data loss prevention (DLP) tools monitor data movement and prevent sensitive information from leaving the organization’s control. Integration with security information and event management (SIEM) systems allows for real-time monitoring of security events and facilitates prompt responses to potential threats. For example, an ERP system might automatically redact credit card numbers in reports, preventing their exposure to unauthorized personnel. DLP tools could prevent employees from emailing sensitive financial data outside the organization’s network. By leveraging these features, organizations can significantly enhance their data protection posture.

Industry-Specific ERP Solutions: Erp Software Software

Generic ERP systems offer a broad range of functionalities, but their effectiveness can be significantly enhanced by tailoring them to the specific needs of different industries. Industry-specific ERP solutions incorporate pre-configured modules and functionalities designed to address the unique operational requirements, regulatory compliance needs, and industry best practices of particular sectors. This results in increased efficiency, improved decision-making, and a stronger competitive advantage.

Industry-specific ERP solutions are not simply generic systems with minor adjustments; they are built from the ground up to address the nuances of a particular industry. This means considering factors such as specialized processes, unique reporting requirements, and integration with industry-specific technologies. The result is a system that is more intuitive, more efficient, and ultimately, more valuable to the business.

Examples of Industry-Specific ERP Solutions

The following table highlights examples of ERP solutions tailored for specific industries, illustrating their key features and benefits. Note that many ERP vendors offer industry-specific modules that can be added to their core systems, rather than entirely separate products.

| Industry | ERP Solution Example (Illustrative) | Key Features | Benefits |

|---|---|---|---|

| Manufacturing | SAP ERP, Oracle NetSuite | Production planning, materials management, quality control, shop floor control, maintenance management | Optimized production processes, reduced inventory costs, improved quality control, enhanced traceability |

| Retail | Oracle Retail, Microsoft Dynamics 365 Commerce | Point-of-sale (POS) integration, inventory management, supply chain management, customer relationship management (CRM), omnichannel capabilities | Improved inventory accuracy, enhanced customer experience, optimized supply chain, increased sales |

| Healthcare | Epic, Cerner Millennium | Patient management, electronic health records (EHR), billing and coding, regulatory compliance (HIPAA), physician scheduling | Improved patient care, streamlined workflows, reduced administrative burden, enhanced regulatory compliance |

| Financial Services | Temenos, Finastra Fusion | Risk management, regulatory compliance, core banking, fraud detection, customer relationship management (CRM) | Improved risk management, enhanced regulatory compliance, streamlined operations, reduced costs |

| Education | Blackbaud, CampusNexus | Student information systems (SIS), financial management, human resources management, alumni relations | Improved student management, enhanced financial control, streamlined administrative processes |

Comparison of Industry-Specific ERP Functionalities

Manufacturing ERP systems prioritize production planning, materials management, and quality control. Retail ERP systems focus on point-of-sale integration, inventory management, and customer relationship management to optimize sales and customer experience. In contrast, healthcare ERP systems prioritize patient management, electronic health records, and regulatory compliance to ensure patient safety and efficient operations. Each system’s functionality is tailored to the specific processes and data requirements of its respective industry.

Addressing Unique Industry Needs

Industry-specific ERP solutions cater to unique needs by incorporating features directly relevant to the industry’s challenges and best practices. For example, manufacturing ERP systems often include features for managing complex bill of materials (BOMs) and tracking work-in-progress (WIP) inventory. Retail ERP systems might integrate with loyalty programs and offer advanced analytics for sales forecasting and promotion planning. Healthcare ERP systems must comply with strict regulations regarding patient data privacy and security, often integrating with specialized medical devices and systems. These tailored functionalities ensure efficient operations and provide valuable insights specific to each industry.

Future Trends in ERP Software

The landscape of Enterprise Resource Planning (ERP) software is constantly evolving, driven by technological advancements and the ever-changing needs of businesses. Future trends are shaping ERP systems into more intelligent, adaptable, and integrated solutions, ultimately enhancing operational efficiency and strategic decision-making. These advancements are impacting how businesses operate, collaborate, and compete in the global marketplace.

The integration of artificial intelligence (AI) and machine learning (ML) is revolutionizing ERP functionality. These technologies are enabling predictive analytics, automated processes, and improved decision support capabilities within ERP systems. This leads to increased efficiency, reduced operational costs, and improved forecasting accuracy.

AI and Machine Learning Integration in ERP

AI and ML are transforming ERP systems from mere transactional databases into intelligent platforms capable of proactive problem-solving and predictive analysis. For example, AI-powered chatbots can handle routine customer inquiries, freeing up human resources for more complex tasks. ML algorithms can analyze sales data to predict future demand, enabling businesses to optimize inventory management and avoid stockouts or overstocking. Predictive maintenance, enabled by ML analysis of equipment data, allows businesses to anticipate potential failures and schedule maintenance proactively, minimizing downtime and maximizing operational efficiency. Furthermore, AI-powered anomaly detection can identify unusual patterns in financial transactions, flagging potential fraud or errors for immediate attention.

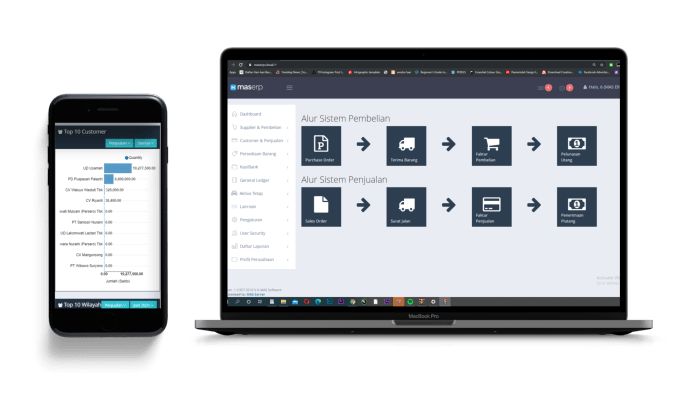

Cloud Computing and Mobile Accessibility in ERP

The shift towards cloud-based ERP solutions is accelerating, offering significant advantages in terms of scalability, accessibility, and cost-effectiveness. Cloud ERP eliminates the need for on-premise servers and IT infrastructure, reducing capital expenditure and freeing up IT resources. Moreover, cloud-based ERP systems are accessible from anywhere with an internet connection, enabling employees to access critical data and applications remotely. This enhanced mobility empowers employees to work more efficiently and collaboratively, regardless of location. Companies like Salesforce and SAP have successfully transitioned to cloud-based models, demonstrating the viability and scalability of this approach. Mobile accessibility further extends this reach, allowing for real-time data access and updates from smartphones and tablets, empowering field workers and on-the-go executives with critical information.

The Role of ERP in Digital Transformation

ERP systems are playing a pivotal role in enabling digital transformation across various industries. By integrating various business functions, ERP provides a single source of truth for data, facilitating better collaboration and decision-making. This unified data platform allows businesses to gain valuable insights into their operations, identify areas for improvement, and optimize processes for increased efficiency and profitability. ERP’s role in digital transformation also extends to its integration with other technologies like IoT (Internet of Things) and blockchain, enabling businesses to leverage data from connected devices and secure supply chains. For instance, a manufacturing company might use ERP to track production data from IoT sensors on machinery, providing real-time insights into production efficiency and potential bottlenecks. This data-driven approach enables continuous improvement and fosters a culture of innovation.

Case Studies of ERP Implementations

Successful ERP implementations can significantly improve operational efficiency, streamline business processes, and enhance decision-making. Conversely, poorly planned or executed projects can lead to significant cost overruns, disruptions to operations, and ultimately, project failure. Analyzing both successful and unsuccessful case studies provides valuable insights for organizations considering ERP adoption.

Successful ERP Implementation: ABC Manufacturing

ABC Manufacturing, a mid-sized company producing automotive parts, implemented an ERP system to address challenges related to inventory management and production scheduling. Prior to implementation, they relied on disparate systems, leading to inaccurate inventory data and production delays. The new ERP system integrated all aspects of their business, from order entry to shipping. The result was a 20% reduction in inventory costs, a 15% increase in on-time delivery, and a significant improvement in overall operational efficiency. The project was successful due to thorough planning, strong executive sponsorship, and effective change management.

Successful ERP Implementation: XYZ Retail

XYZ Retail, a large national retailer, implemented an ERP system to improve supply chain visibility and customer relationship management. Before the implementation, managing inventory across numerous locations was a significant challenge. The new ERP system provided real-time inventory tracking, enabling better forecasting and reduced stockouts. Furthermore, the integration of customer data allowed for personalized marketing campaigns and improved customer service. The project’s success can be attributed to a phased implementation approach, rigorous testing, and ongoing training for employees. They saw a 10% increase in sales and a 5% reduction in customer service calls within the first year.

Unsuccessful ERP Implementation: DEF Services

DEF Services, a small consulting firm, attempted to implement an ERP system without sufficient planning or resources. The chosen system was overly complex and did not adequately address their specific business needs. Lack of proper training and inadequate change management led to widespread employee resistance. The project ultimately failed, resulting in significant financial losses and disruption to operations. The key takeaway from this case study is the importance of thorough needs assessment, selecting the right system, and investing in adequate training and support.

ERP Implementation Lessons Learned: Importance of Change Management

Effective change management is crucial for successful ERP implementation. This involves communicating the benefits of the new system to employees, providing adequate training, and addressing concerns. Ignoring this aspect can lead to resistance, decreased productivity, and ultimately, project failure. Both ABC Manufacturing and XYZ Retail prioritized change management, resulting in smoother transitions and higher employee adoption rates. In contrast, DEF Services’ failure highlights the critical role of change management in ERP success.

ERP Implementation Lessons Learned: Selecting the Right System

Choosing the right ERP system is paramount. The system should align with the organization’s specific business needs, size, and industry. A system that is too complex or lacks essential features can lead to difficulties in implementation and usage. ABC Manufacturing carefully evaluated various ERP systems before selecting one that met their specific requirements. DEF Services’ experience underscores the importance of a thorough evaluation process to avoid selecting an unsuitable system.

Summary

Implementing ERP software represents a significant investment, but the potential benefits—increased efficiency, improved data visibility, and enhanced decision-making—are substantial. By carefully considering the factors Artikeld in this guide, businesses can navigate the selection and implementation process effectively, maximizing their return on investment and achieving a seamless integration with existing systems. The future of ERP software is bright, with ongoing advancements in AI, cloud computing, and mobile accessibility promising even greater efficiency and capabilities.